Executive Summary

Inventory management is the process of ordering, storing, tracking, and controlling a company’s inventory to ensure that the right products are available at the right time, in the right quantity, and at optimal costs. Effective inventory management balances supply and demand, reduces holding costs, minimizes stockouts, and improves overall operational efficiency.

Inventory management is critical for businesses of all sizes, from small retailers to large multinational manufacturers. Proper inventory control ensures smooth operations, customer satisfaction, and maximized profitability.

This guide explores inventory management, its types, processes, methods, benefits, challenges, tools, strategies, and best practices, providing a comprehensive resource for business professionals, supply chain managers, and entrepreneurs.

Table of Content

Introduction

Inventory is the lifeblood of most businesses. Whether it’s raw materials, work-in-progress items, or finished goods, proper inventory management is essential to maintain operations, satisfy customers, and optimize financial performance.

Without inventory management, businesses risk overstocking, understocking, high carrying costs, and lost sales opportunities. Inventory management is therefore a strategic function that impacts production efficiency, cash flow, and competitive advantage.

Inventory management is not just a warehouse or stock-keeping function—it is a systematic approach that integrates purchasing, production, logistics, and sales to ensure resources are used efficiently and inventory aligns with business goals.

Origins and Evolution of Inventory Management

Inventory management has evolved alongside business practices and technology. Understanding its history provides context for modern approaches:

- Manual Record-Keeping (Pre-20th Century) – Businesses tracked inventory manually using ledgers and stock cards. Accuracy was limited, and errors were common.

- Economic Order Quantity (EOQ) Model (Early 20th Century) – Introduced by Ford W. Harris, EOQ helped businesses determine optimal order quantities to minimize costs.

- Just-in-Time (JIT) and Lean Practices (Mid-20th Century) – Toyota pioneered JIT, emphasizing inventory minimization and efficiency.

- Computerized Inventory Systems (Late 20th Century) – The advent of ERP systems allowed real-time tracking, automation, and improved reporting.

- Modern Inventory Management (21st Century) – Integration with supply chain management, AI analytics, and cloud-based platforms enables predictive and demand-driven inventory strategies.

Core Principles of Inventory Management

Successful inventory management relies on several foundational principles:

- Accuracy – Inventory records must reflect actual stock levels to prevent shortages or excesses.

- Visibility – Real-time tracking of inventory across locations ensures timely decisions.

- Balance of Supply and Demand – Inventory should meet customer demand without overstocking.

- Cost Control – Minimize holding costs, ordering costs, and wastage.

- Efficiency – Streamline processes for receiving, storing, tracking, and distributing inventory.

- Forecasting and Planning – Predict demand and plan inventory accordingly.

- Safety Stock Management – Maintain buffer stock to avoid stockouts during fluctuations.

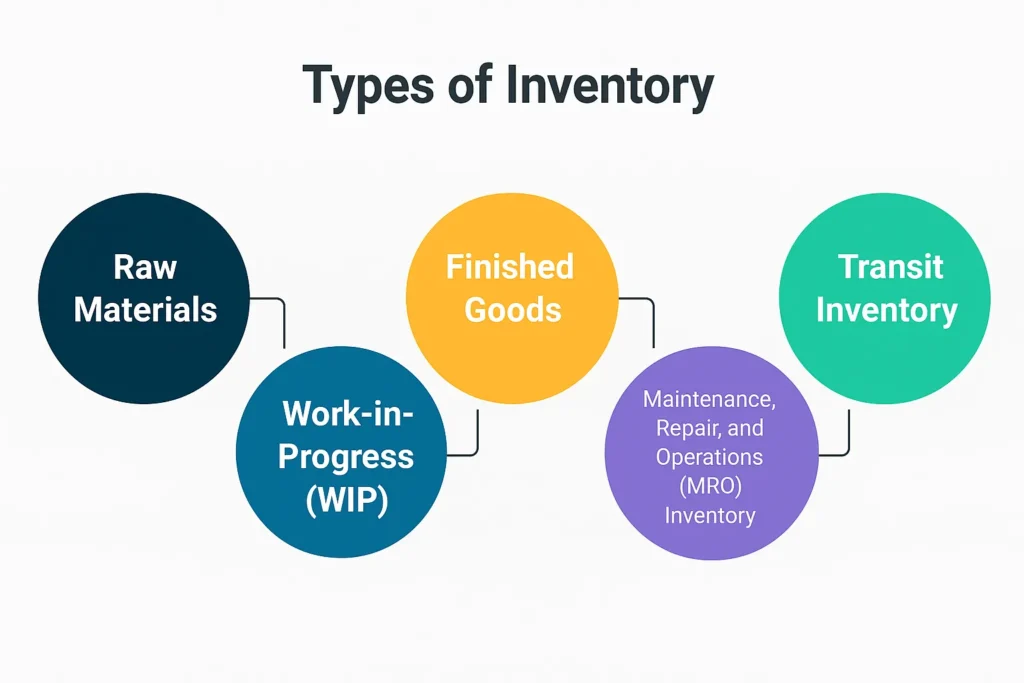

Types of Inventory

Inventory can take different forms depending on the business type and operational processes:

1. Raw Materials

- Basic inputs used in production processes.

- Example: Steel for automotive manufacturing, fabric for clothing production.

2. Work-in-Progress (WIP)

- Items that are in the production process but not yet finished.

- Example: Partially assembled electronics.

3. Finished Goods

- Products ready for sale to customers.

- Example: Packaged snacks in a supermarket.

4. Maintenance, Repair, and Operations (MRO) Inventory

- Supplies used to support production and operations but not part of final products.

- Example: Cleaning supplies, lubricants, tools.

5. Transit Inventory

- Goods moving between suppliers, warehouses, or stores.

- Example: Items in delivery trucks or shipping containers.

Inventory Management Processes

Inventory management involves systematic processes to ensure efficiency and accuracy:

1. Demand Forecasting

- Analyze historical sales, market trends, and seasonal factors to predict future demand.

- Helps optimize stock levels and reduce excess or shortage.

2. Procurement and Reordering

- Determine when and how much to order using reorder points and EOQ.

- Supplier relationship management ensures timely delivery and cost efficiency.

3. Receiving and Inspection

- Verify incoming inventory against purchase orders.

- Inspect for quality, damage, or discrepancies before storage.

4. Storage and Warehousing

- Store inventory in organized locations using bins, shelves, or racks.

- Implement proper labeling, categorization, and handling procedures.

5. Inventory Tracking

- Use technology (barcodes, RFID, ERP systems) to track stock levels in real-time.

- Helps prevent theft, loss, and misplacement.

6. Stock Rotation

- Apply techniques like FIFO (First In, First Out) or LIFO (Last In, First Out) to manage product lifecycle.

- Reduces waste and obsolescence.

7. Reporting and Analysis

- Generate reports on stock levels, turnover rates, carrying costs, and performance.

- Supports strategic decisions and process improvements.

8. Inventory Optimization

- Adjust stock levels to minimize costs while meeting demand.

- Includes safety stock planning, buffer inventory, and lead time adjustments.

Inventory Management Methods and Techniques

Businesses use various methods to control inventory efficiently:

1. Economic Order Quantity (EOQ)

- Determines the optimal order quantity that minimizes total inventory costs.

2. Just-in-Time (JIT)

- Inventory is ordered and received only when needed.

- Reduces holding costs but requires reliable supply chains.

3. ABC Analysis

- Categorizes inventory based on value and importance:

- A: High-value items, tight control

- B: Moderate-value items

- C: Low-value items, minimal control

4. First-In, First-Out (FIFO)

- Oldest stock is sold first to prevent obsolescence.

5. Last-In, First-Out (LIFO)

- Most recent stock is used or sold first; sometimes used for accounting purposes.

6. Safety Stock Management

- Maintains buffer stock to avoid stockouts due to unexpected demand or supply delays.

7. Vendor-Managed Inventory (VMI)

- Suppliers monitor inventory and manage replenishment, reducing administrative effort for the business.

8. Perpetual and Periodic Inventory Systems

- Perpetual: Real-time tracking of inventory levels using software.

- Periodic: Physical counting at regular intervals to update records.

Roles in Inventory Management

Effective inventory management requires coordination among multiple roles:

- Inventory Manager / Stock Controller – Oversees inventory processes, ensures optimal stock levels.

- Procurement Officer / Buyer – Manages purchasing, supplier relationships, and order quantities.

- Warehouse Staff – Handles receiving, storing, picking, and packing of goods.

- Supply Chain Analyst – Forecasts demand, monitors trends, and evaluates inventory performance.

- Operations Manager – Coordinates inventory management with production and logistics.

- IT Specialist / ERP Administrator – Manages inventory software and data systems.

Tools and Technologies in Inventory Management

Modern inventory management leverages technology to streamline operations:

- ERP Systems: SAP, Oracle NetSuite, Microsoft Dynamics.

- Inventory Management Software: Zoho Inventory, TradeGecko, Fishbowl, Odoo.

- Barcode and RFID Systems: Track inventory movement and improve accuracy.

- Warehouse Management Systems (WMS): Optimize storage, picking, and shipping processes.

- Analytics Tools: Tableau, Power BI, or built-in dashboards to monitor KPIs.

- Automation and Robotics: Automated picking, sorting, and replenishment in warehouses.

Benefits of Inventory Management

- Optimized Stock Levels – Avoid overstocking and stockouts.

- Reduced Holding Costs – Efficient storage and lower capital tied in inventory.

- Improved Cash Flow – Money isn’t unnecessarily locked in inventory.

- Enhanced Customer Satisfaction – Products are available when and where needed.

- Better Demand Planning – Accurate forecasting reduces waste and missed opportunities.

- Operational Efficiency – Streamlined processes save time and labor costs.

- Data-Driven Decision-Making – Accurate reports support strategic planning.

- Reduced Obsolescence and Waste – Proper rotation and tracking prevent spoilage.

Challenges in Inventory Management

- Demand Variability: Unpredictable market trends or seasonal fluctuations.

- Supply Chain Disruptions: Delays, transportation issues, or supplier problems.

- Data Inaccuracy: Errors in records or manual tracking can cause inefficiency.

- Overstocking or Stockouts: Imbalance leads to higher costs or lost sales.

- Storage Limitations: Insufficient warehouse space or poor organization.

- Obsolescence: Unsold inventory can become outdated or spoiled.

- Cost Management: Balancing ordering costs, holding costs, and stock availability.

Metrics and KPIs

Key performance indicators help measure inventory management effectiveness:

- Inventory Turnover Ratio – Measures how frequently inventory is sold and replaced.

- Days of Inventory on Hand (DOH) – Average number of days inventory is held before sale.

- Stockout Rate – Percentage of times items are unavailable when needed.

- Carrying Cost of Inventory – Total cost of holding inventory, including storage, insurance, and depreciation.

- Order Accuracy Rate – Percentage of orders fulfilled correctly.

- Lead Time – Time from ordering to receiving stock.

- Shrinkage Rate – Loss of inventory due to theft, damage, or errors.

Inventory Management Strategies

- Align Inventory with Demand – Use forecasting and analytics to predict sales and plan stock levels.

- Adopt Just-in-Time or Lean Approaches – Minimize excess inventory and reduce holding costs.

- Categorize Inventory with ABC Analysis – Focus resources on high-value items.

- Automate Processes – Use technology for tracking, replenishment, and reporting.

- Regular Auditing – Conduct cycle counts and audits to ensure accuracy.

- Collaborate with Suppliers – Improve reliability, lead times, and VMI processes.

- Implement Safety Stock – Prepare for unexpected demand spikes or delays.

Real-World Applications

- Retail: Maintaining optimal stock of consumer goods to meet customer demand.

- Manufacturing: Managing raw materials, WIP, and finished goods to support production schedules.

- E-Commerce: Tracking inventory across warehouses and dropshipping networks for fast delivery.

- Healthcare: Ensuring availability of medicines, surgical tools, and supplies.

- Food & Beverage: Managing perishable goods to reduce waste and spoilage.

Common Misconceptions

- Inventory Management is Only Counting Stock – It is a strategic process involving forecasting, planning, and optimization.

- More Inventory Means Better Preparedness – Excess inventory ties up capital and increases costs.

- Manual Methods Are Enough – Technology and automation improve accuracy and efficiency.

- Inventory Management is Only for Large Companies – Small and medium enterprises also benefit from structured inventory practices.

Steps to Implement Inventory Management

- Assess Current Inventory Practices – Identify inefficiencies, stock issues, and technology gaps.

- Select an Inventory Management System – Choose software or ERP solutions suited to your business.

- Define Inventory Policies – Set reorder points, safety stock levels, and handling procedures.

- Train Staff and Establish Roles – Ensure employees understand processes and responsibilities.

- Track and Monitor Inventory – Use real-time data for accuracy and decision-making.

- Analyze and Optimize – Regularly review KPIs and adjust strategies to reduce costs and improve service.

- Integrate with Supply Chain – Align inventory management with procurement, production, and distribution.

Future of Inventory Management

Inventory management is evolving with technology, customer expectations, and global supply chains:

- AI and Predictive Analytics – Forecast demand and optimize inventory levels.

- IoT and Smart Warehouses – Real-time monitoring and automated stock handling.

- Cloud-Based Systems – Centralized data for multi-location management.

- Sustainability Focus – Reduce waste and optimize resource usage.

- Omnichannel Integration – Coordinate inventory across physical stores, e-commerce, and distribution centers.

Conclusion

Inventory management is a critical component of business operations, ensuring that products are available when needed while minimizing costs and waste.

By adopting best practices, leveraging technology, and integrating inventory strategies with supply chain and business goals, organizations can improve efficiency, profitability, and customer satisfaction. Effective inventory management transforms inventory from a simple resource into a strategic asset that drives operational excellence and competitive advantage.

Related Articles on Operational Efficiency

Modern inventory success depends on how well businesses synchronize supply, logistics, and workforce strategies.

- For a closer look at retail and procurement alignment, explore What Is Category Management?, which explains how inventory planning connects to supplier strategies.

- To see how vehicle and delivery operations enhance stock movement, read How Smart Fleet Management Improves Efficiency, Safety, and Sustainability.

- Behind every smooth inventory process is an optimized team — What Is Workforce Management? explores staff scheduling and productivity approaches for inventory-heavy industries.

- Lastly, to understand how assets and personnel align for seamless logistics, What Is Resource Coordination in Incident Management provides insights into real-time coordination strategies.