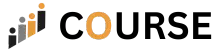

What will you learn in Brother Scan N Cut – Cut, Draw and Scan With Confidence Course

Set up and calibrate your Brother ScanNCut machine for precise cutting and drawing

Navigate and customize CanvasWorkspace software: designing, importing, and editing cutting files

Use built-in patterns and create your own vector shapes for personalized projects

Scan hand-drawn art and convert it to cut-ready paths, then adjust sensitivity and trace settings

Maintain your machine: blade cleaning, mat care, and firmware updates for consistent performance

Program Overview

Module 1: Introduction & Machine Setup

⏳ 30 minutes

Topics: Unboxing your ScanNCut, hardware overview, power/data connections

Hands-on: Complete first-time setup and perform an alignment test cut

Module 2: CanvasWorkspace Basics

⏳ 1 hour

Topics: Software installation, interface tour, importing pre-made designs

Hands-on: Load a sample SVG, resize for cutting, and send to machine

Module 3: Designing Custom Shapes

⏳ 1 hour

Topics: Drawing primitives, path editing tools, combining shapes and text

Hands-on: Create a layered greeting-card design with text and decorative borders

Module 4: Scan & Trace Workflow

⏳ 45 minutes

Topics: Scanning hand-drawn sketches, adjusting trace threshold, smoothing paths

Hands-on: Scan a doodle, trace it into vector form, and cut as a sticker

Module 5: Advanced Cutting & Drawing Techniques

⏳ 1 hour

Topics: Multi-pass cutting, kiss cutting, tool changers (blade vs. pen), speed/pressure presets

Hands-on: Draw detailed pen work on cardstock, then perform a precise kiss-cut layer

Module 6: Project Applications

⏳ 45 minutes

Topics: Vinyl decals, iron-on transfers, paper crafts, fabric applique basics

Hands-on: Design and cut a custom vinyl decal for a mug and apply it

Module 7: Maintenance & Troubleshooting

⏳ 30 minutes

Topics: Blade cleaning and replacement, mat care, firmware updates, common error codes

Hands-on: Practice removing and cleaning the blade assembly; update machine firmware

Module 8: Final Capstone Project

⏳ 1 hour

Topics: End-to-end workflow planning, multi-material layering, file organization best practices

Hands-on: Plan and execute a multi-layered project (e.g., custom greeting card with vinyl embellishments)

Get certificate

Job Outlook

Skills with the Brother ScanNCut open doors to small-business crafting, Etsy storefronts, and home DIY project services

Crafters proficient in vinyl, paper, and fabric cutting can offer custom decals, apparel embellishments, and greeting cards

Freelance rates range $20–$50 per hour for project-based work; experienced designers can scale to full online shops

Specification: Brother Scan N Cut – Cut, Draw and Scan With Confidence

|

FAQs

- The course focuses on using the Brother ScanNCut for personal and creative projects.

- Skills like cutting, drawing, and scanning designs can be applied to small-scale commercial projects.

- You’ll need to check Brother’s licensing terms if selling products made with their software or designs.

- Understanding file formats and design precision is key for professional-quality outputs.

- Techniques learned can be adapted for hobby businesses like custom cards or home décor.

- No prior experience is required; the course starts with beginner-friendly instructions.

- Step-by-step guidance helps users understand cutting, scanning, and drawing functions.

- Basic knowledge of design software can be helpful but isn’t mandatory.

- Learners are introduced to tools, settings, and safety practices gradually.

- Practice with simple projects builds confidence before attempting complex designs.

- The course covers layering techniques to some extent for more intricate designs.

- True 3D projects may require combining multiple cut layers manually.

- Understanding scan and cut precision is essential for aligning layered elements.

- Learners can experiment with paper, vinyl, and fabric to create depth in designs.

- Advanced 3D modeling may need additional software outside this course.

- Yes, the course teaches scanning hand-drawn or digital artwork into compatible formats.

- You’ll learn how to clean up designs and optimize them for cutting or drawing.

- Techniques include adjusting size, smoothing lines, and selecting cut paths.

- Understanding file compatibility ensures designs translate accurately to the machine.

- These skills allow personalizing projects with original artwork efficiently.

- The course provides basic guidance on error messages and calibration issues.

- Learners gain confidence in adjusting settings and maintaining the machine.

- More complex mechanical or software issues may require consulting the user manual.

- Understanding proper setup reduces errors during cutting or drawing.

- Regular maintenance practices are emphasized to prevent recurring problems.