What will you in PLC Fundamentals (Level I) Course

- Understand PLC architecture, hardware components, and software environments.

- Develop and simulate ladder logic programs using industry-standard platforms.

- Implement timers, counters, and advanced instructions for process control.

- Design sequenced and conditional control flows for real-world automation tasks.

- Integrate Human-Machine Interfaces (HMIs) and basic SCADA concepts.

- Configure industrial communication protocols (Modbus, Ethernet/IP) for device networking.

Program Overview

Module 1: Introduction to PLCs & Software Setup

⏳ 45 minutes

Overview of PLC hardware: CPUs, I/O modules, power supplies.

Install and configure the PLC programming environment (e.g., RSLogix, TIA Portal).

Understand simulation tools and setup a virtual PLC for practice.

Module 2: Ladder Logic Fundamentals

⏳ 1 hour

Learn basic ladder elements: contacts, coils, and power rails.

Create simple on/off control circuits and test in simulator.

Apply rung organization and commenting for maintainable code.

Module 3: Timers, Counters & Data Handling

⏳ 1 hour

Configure on-delay, off-delay, and retentive timers.

Implement up/down counters and compare operations.

Use data registers, move instructions, and arithmetic operations.

Module 4: Sequencing & Advanced Instructions

⏳ 1 hour

Design multi-step process sequences with state machines.

Utilize advanced instructions: PID, shift registers, and mask/compare.

Integrate subroutines and modular function blocks for reuse.

Module 5: HMI Integration & SCADA Basics

⏳ 1 hour

Create graphical interfaces: buttons, indicators, and trends.

Link HMI tags to PLC addresses and simulate operator interaction.

Understand SCADA architecture and data acquisition fundamentals.

Module 6: Industrial Networking & Protocols

⏳ 45 minutes

Explore Modbus RTU/TCP and Ethernet/IP configuration.

Set up communication between multiple PLCs and HMIs.

Diagnose network issues using built-in protocol monitors.

Module 7: Hands-On Projects & Case Studies

⏳ 1 hour

Build a conveyor belt control system with start/stop sequences.

Implement safety interlocks and emergency stop logic.

Review real-world automation scenarios and best practices.

Module 8: Troubleshooting & Maintenance

⏳ 45 minutes

Use diagnostic tools: watch windows, force I/O, and error logs.

Identify and resolve common programming and wiring faults.

Apply preventive maintenance strategies to ensure uptime.

Get certificate

Job Outlook

- High-Demand Roles: PLC Programmer, Automation Engineer, Controls Technician.

- Salary Potential: ₹4–12 LPA in India; $60K–$85K annually in the U.S.

- Growth Areas: Industrial automation, Industry 4.0, robotics, and IIoT connectivity.

- Career Pathways: Leads to roles in system design, project management, and control systems architecture.

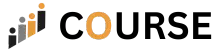

Specification: PLC Fundamentals (Level I)

|